(812) 458-98-38 lenturbo@yandex.ru СПб, Уманский пер., д.78, лит. А

Разработки

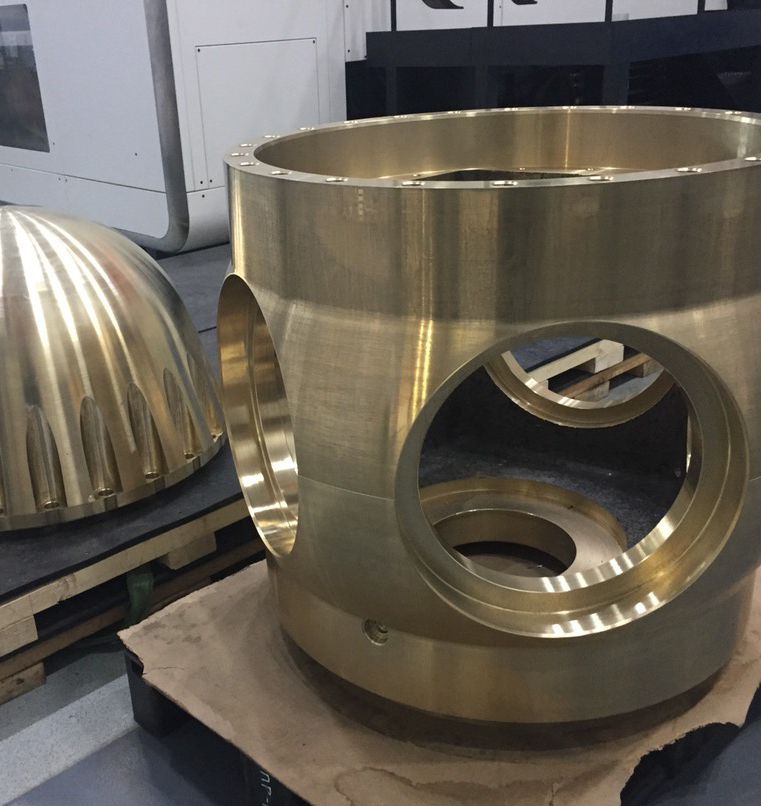

Производство лопаток паровых и газовых турбин

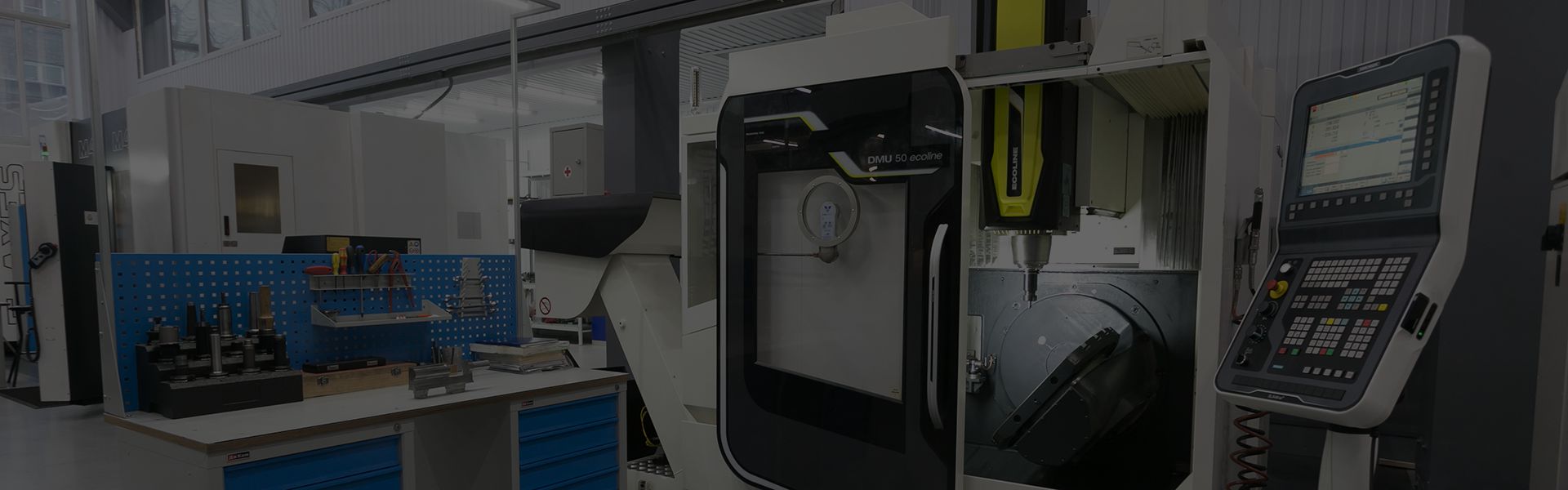

Расширяя свои производственные возможности, компания освоила производство рабочих и направляющих лопаток для паровых и газовых турбин, компрессоров, ГПА.

Выполнен ряд проектов по инжинирингу и обратному реинжинирингу элементов проточной части с восстановлением технической документации, изготовлением и монтажом готовых изделий.

Система заградительного охлаждения выхлопной части ЦНД

- Разработка базового технического решения задачи охлаждения выхлопной части ЦНД турбин мощностью 200-800 МВт на пусковом режиме при снижении температурных градиентов на рабочих лопатках последних ступеней, предотвращающих эрозионное повреждение их выходных кромок и увеличивающих надежность паяных соединений на входных кромках.

- Разработка компоновочной схемы системы заградительного охлаждения (СЗО).

- Разработка рабочего проекта устройства приготовления СЗО.

- Разработка рабочего проекта направляющего аппарата СЗО.

- Разработка рабочего проекта трубопроводов парообеспечения СЗО.

- Разработка рабочего проекта и изготовление оптических измерительных узлов системы визуального контроля выхлопного патрубка ЦНД.

- Разработка технической документации, изготовление средств дополнительного температурного контроля.

- Разработка технологического процесса и изготовление направляющего аппарата кольцевой камеры для каждого выхлопа прямого и обратного потоков.

- Разработка технологии монтажа СЗО и трубопроводов парообеспечения.

- Техническое руководство работами по монтажу и проведению наладки СЗО на пусковых режимах турбоагрегата.

- Проведение оптического контроля эрозионного состояния выходных кромок рабочих лопаток последней ступени одного из потоков ЦНД.

- Техническое руководство монтажом средств дополнительного контроля.